R-410a temperature glide can range from – R-410A temperature glide, a crucial aspect of refrigeration systems, has a specific range that significantly influences system performance. This article delves into the temperature glide of R-410A, exploring its implications and the factors that affect it.

The temperature glide of R-410A, a blend of HFC refrigerants, is a key factor in determining the efficiency and capacity of refrigeration systems. Understanding its range and impact enables engineers to optimize system design and performance.

R-410A Temperature Glide Range: R-410a Temperature Glide Can Range From

Temperature glide is a crucial property of refrigerants that affects the performance of refrigeration systems. It refers to the difference in temperature between the condensing and evaporating temperatures of a refrigerant during a phase change process. R-410A, a commonly used refrigerant, has a specific temperature glide range that influences its system performance and design considerations.

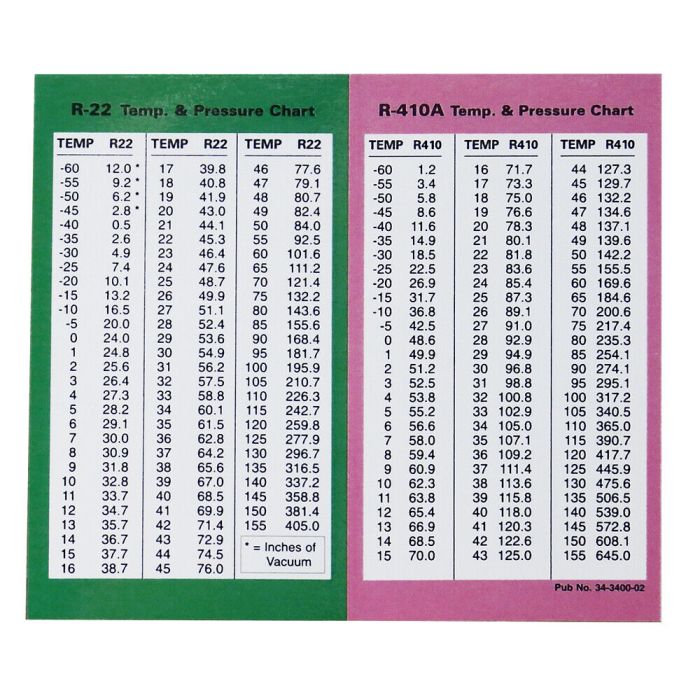

The temperature glide range of R-410A typically varies between 5 to 10°C (9 to 18°F). This range indicates that during condensation, R-410A undergoes a gradual phase change, transitioning from a vapor to a liquid state over a temperature difference of 5 to 10°C.

Similarly, during evaporation, R-410A changes from a liquid to a vapor state over the same temperature difference.

Factors that influence the temperature glide of refrigerants include molecular structure, pressure, and composition. The molecular structure of R-410A, a blend of HFC-32 and HFC-125, contributes to its specific temperature glide range.

Effects of Temperature Glide on System Performance

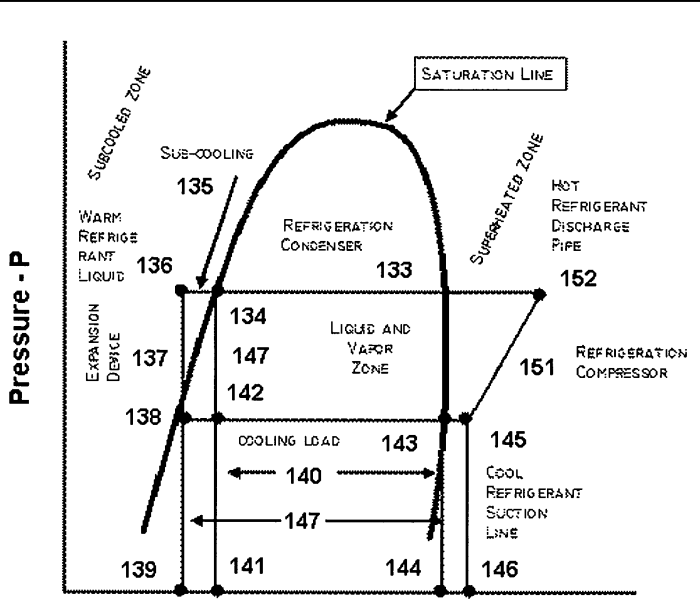

Temperature glide has a significant impact on the efficiency and capacity of refrigeration systems. A larger temperature glide can lead to reduced system efficiency due to increased energy consumption during the compression process.

In a refrigeration system with a large temperature glide, the compressor must work harder to overcome the pressure difference between the condenser and evaporator. This increased work results in higher energy consumption and reduced system efficiency. Additionally, a larger temperature glide can affect the capacity of the system, as the refrigerant may not be able to absorb as much heat during evaporation.

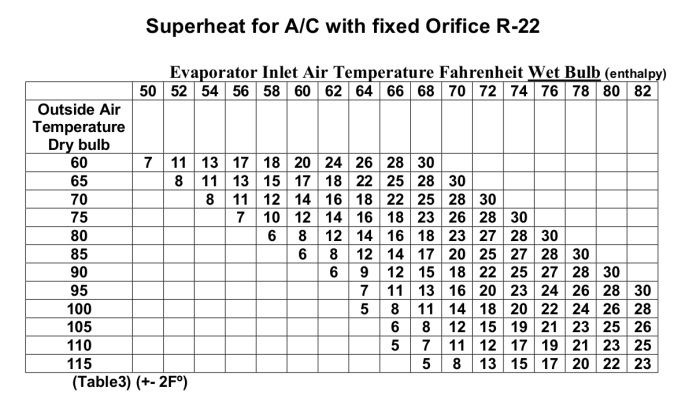

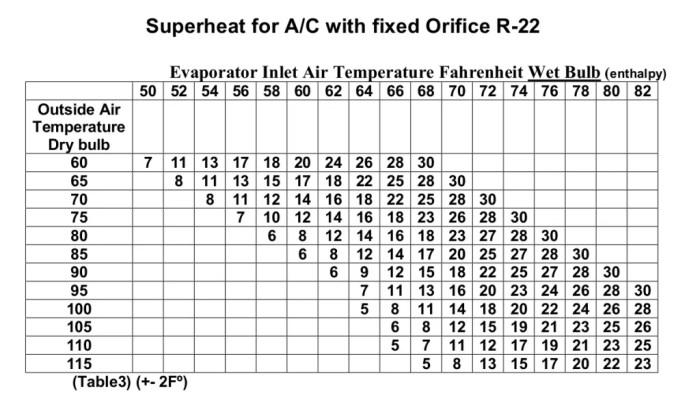

Design considerations for optimizing system performance in the presence of temperature glide include selecting appropriate compressor technology, optimizing refrigerant charge, and implementing measures to reduce pressure drop in the system.

Applications and Limitations of R-410A

R-410A is commonly used in residential and commercial air conditioning and heat pump systems due to its high efficiency, low ozone depletion potential, and relatively low global warming potential. It is a suitable refrigerant for applications requiring a medium temperature glide range.

However, R-410A has limitations, including its high operating pressure, which requires specialized equipment and safety precautions. Additionally, R-410A is a potent greenhouse gas, and its use is being phased out in some regions due to environmental concerns.

Alternative refrigerants with similar temperature glide requirements include R-32, R-454B, and R-452B. These refrigerants offer varying levels of efficiency, environmental impact, and safety considerations.

Recent Developments and Future Trends

Research and development efforts are ongoing to improve temperature glide management in refrigeration systems. Advances in refrigerant blends and compressor technologies aim to reduce temperature glide and enhance system efficiency.

Emerging trends in temperature glide management include the use of variable-speed compressors, electronic expansion valves, and advanced control algorithms. These technologies allow for precise control of refrigerant flow and temperature, optimizing system performance and reducing energy consumption.

Future developments in temperature glide management are expected to focus on the development of low-glide refrigerants with improved environmental properties and the integration of advanced technologies for system optimization.

FAQ Compilation

What is temperature glide in refrigeration systems?

Temperature glide refers to the difference between the condensing temperature and evaporating temperature of a refrigerant during a phase change process.

How does temperature glide affect system efficiency?

Higher temperature glide can lead to reduced efficiency due to increased compressor work and energy consumption.

What factors influence the temperature glide of refrigerants?

Factors such as refrigerant composition, pressure, and temperature can affect the temperature glide of refrigerants.